- All

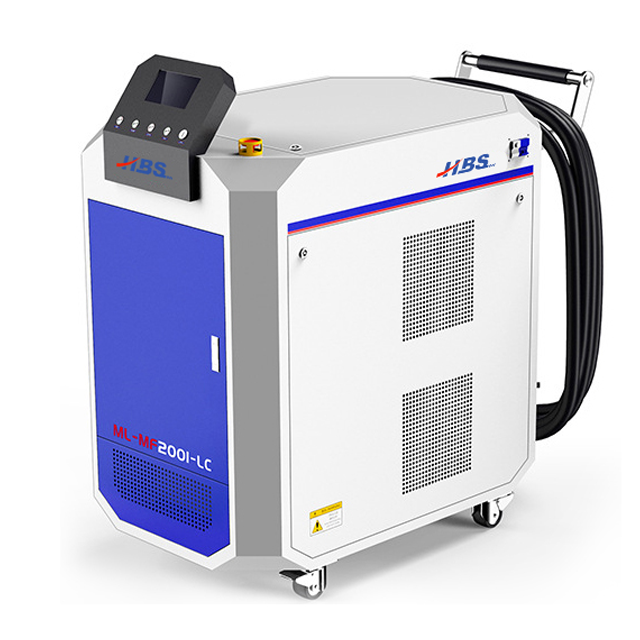

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

In heavy industry and large-scale manufacturing, removing thick layers of rust, paint, or scale from large surfaces is a constant challenge. Whether you operate a steel mill, shipyard, foundry, or fabrication shop, maintenance teams regularly spend hours—or even days—sandblasting, power-washing, or chemically stripping worn components. These traditional processes are labor-intensive, environmentally taxing, and can damage precision surfaces.

Laser cleaning machines offer a compelling alternative for large-area, heavy-duty applications. By delivering high-energy laser pulses that selectively vaporize or fracture contaminant layers, these systems can strip coatings quickly and precisely—without chemicals, abrasives, or excessive water. However, not every laser cleaner is built for continuous, high-throughput use in demanding industrial environments. Choosing the right machine requires careful consideration of power, pulse characteristics, cooling, automation, and total cost.

Why It Matters

Laser output power—measured in kilowatts (kW)—directly impacts how quickly you can remove coatings and the maximum thickness of material you can strip in one pass. Lower-power units (100–500 W) excel at fine, occasional cleaning of oxidation or light paint. In contrast, 1–5 kW systems are designed for:

High-throughput striping of mill scale or heavy rust

Large surface areas spanning multiple square meters per minute

Continuous operation without overtaxing the laser source

How to Choose

Estimate material thickness: For 1 mm of steel scale, a 1 kW fiber laser might clean 4–6 m² per hour; for 3 mm, you’ll need 2–3 kW to maintain throughput.

Match to coverage area: Calculate your daily cleaning volume (m²/day) and select a power class that can meet or exceed that requirement with a healthy safety margin.

Plan for growth: If you foresee ramping up production, opt for the next tier of power to avoid replacing the system later.

Pulse Duration

Nanosecond (ns) Lasers: Widely used in industrial cleaners, ns pulses effectively remove thick coatings but deposit more heat into the substrate.

Picosecond/Femtosecond (ps/fs) Lasers: Ultra-short pulses minimize heat diffusion, reducing thermal stress on precision parts. They excel at micro-cleaning or sensitive surfaces.

Wavelength

Infrared (1,064 nm): Standard for fiber lasers, ideal for metal cleaning and general-purpose stripping.

Green (532 nm) or Ultraviolet (355 nm): Offer higher absorption in non-metallic coatings (paint, oxides) and finer control, but at higher equipment cost.

Balancing Efficiency and Substrate Safety

If you need to strip thick industrial coatings, a 1,064 nm ns system will maximize speed.

For precision maintenance on bearings, sensors, or thin-gauge materials, consider a short-pulse or UV laser to avoid overly heating the base metal.

Continuous Operation Demands

Heavy-duty cleaning often means running the laser head—and its pump diodes—at high duty cycles for hours at a time. Without proper cooling:

Laser efficiency drops as temperature rises.

Lifespan of diodes and optical components decreases.

System instability can lead to unplanned downtime.

Key Features to Look For

Closed-loop water chillers sized to maintain < 30 °C laser head temperature.

Redundant cooling circuits to protect against flow interruptions.

Thermal sensors at critical points with automated shutdown on overheat.

Robot Arms

Pros: High flexibility and range of motion, ideal for complex geometries and multi-axis cleaning.

Cons: Programming complexity and higher capital cost.

Gantry (Cartesian) Units

Pros: Superior positional repeatability (± 0.1 mm), scalable to very large work envelopes, easier offline programming.

Cons: Footprint can be sizable; less dexterity on angled surfaces.

Choosing Your Platform

For irregular parts or in-cell maintenance robots, a six-axis arm may be best.

For flat panels, beams, and rails, a gantry delivers faster cycle times and simpler integration.

Many heavy-industry facilities require zero-downtime maintenance or in-line cleaning of parts moving on conveyors. Look for systems that offer:

Industrial communication protocols (Ethernet/IP, Profinet) to link with PLCs and SCADA.

Triggering options based on positional encoders or vision systems.

Safety interlocks and light curtains to keep operators clear during automated cycles.

Even though laser cleaning produces far less debris than traditional methods like sandblasting or shot blasting, the process still generates vaporized metal oxides, paint fragments, and microscopic particulates that must be managed to protect both personnel and equipment. An effective dust-control and filtration system—integrated directly with the laser cleaning unit—ensures a safe, compliant, and low-maintenance workspace.

1. High-Efficiency Particulate Capture

Local Extraction Hoods: These hoods are strategically positioned within a few centimeters of the laser beam’s path. By capturing debris immediately upon generation, they prevent particles from dispersing into the surrounding air or settling on nearby surfaces. Adjustable nozzles and sliding shrouds allow the hood to follow intricate cleaning patterns without losing suction.

HEPA/ULPA Multistage Filtration: After the initial capture, air passes through a sequence of pre-filters, HEPA (High-Efficiency Particulate Air) filters, and ULPA (Ultra-Low Penetration Air) filters. Each stage progressively removes larger to sub-micron particles—down to 0.1 micrometers—ensuring that even the finest metal oxide dust is retained. Regular pressure-drop monitoring and filter-change indicators simplify maintenance scheduling.

Activated Carbon Adsorption: When cleaning painted or coated surfaces, volatile organic compounds (VOCs) and trace solvents can off-gas. Activated carbon modules placed downstream of the particulate filters adsorb these organic molecules, preventing odors and chemical exposure in the workspace.

2. Impact on Shop-Floor Cleanliness

Implementing a robust filtration solution has immediate, tangible benefits:

Regulatory Compliance: With airborne particulates controlled to below 0.5 mg/m³, operations can align with “clean factory” requirements or ISO 14644-1 cleanroom classifications, avoiding costly fines or production shutdowns.

Reduced Housekeeping: Unlike blasting, there’s no slurry to mop up or grit to sweep. Laser debris is confined to disposable filter cartridges—simply replace and seal them for safe disposal.

Enhanced Air Quality and Worker Safety: By eliminating airborne dust, the system reduces reliance on respiratory PPE, lowers noise compared to abrasive cleaning booths, and creates a more comfortable environment. Cleaner air also protects sensitive electronics and precision machinery from contamination, extending their service life.

Investing in an integrated extraction and filtration package makes laser cleaning not only a high-precision maintenance tool but also a minimal-impact solution for modern, environmentally conscious workshops.

Capital Expense: A 2 kW industrial laser cleaning station might cost $100,000–$150,000, compared to $10,000–$30,000 for a blast cabinet.

Consumables: Lasers require only electricity and occasional filters; sandblasting demands tons of grit and frequent cabinet rebuilds.

Labor Savings: Faster setup, shorter cycle times, and minimal cleanup translate to fewer operator hours.

Break-Even Analysis

Estimate your annual hours of cleaning.

Calculate labor and media costs for traditional methods.

Compare to annual electricity and maintenance costs for the laser.

Most heavy-use facilities see payback within 12–24 months.

Field-Replaceable Modules: Look for systems where diode stacks, pumps, and filters can be swapped by on-site technicians.

Extended Warranties: Vendors offering 3–5 year coverage reduce risk of unexpected repair bills.

Remote Diagnostics: Some machines support real-time monitoring from the manufacturer, speeding up troubleshooting.

Choosing the right laser cleaning machine for demanding industrial applications involves more than just selecting the highest-powered unit. It requires a thoughtful evaluation of:

Power and Throughput: Matching laser output to the thickness of coatings and the size of workpieces ensures you achieve rapid, uniform cleaning across large areas.

Pulse Characteristics: The right combination of pulse duration and wavelength allows you to strip heavy rust or delicate residues without damaging the substrate.

Thermal Management: Robust cooling systems keep your laser operating at peak efficiency during continuous, high-volume production runs.

Automation and Integration: Whether you need a robotic arm for complex geometries or a gantry setup for straight-line cleaning, seamless communication with your existing PLCs and conveyor systems is key.

Total Cost of Ownership: By weighing upfront investment against savings in labor, consumables, and waste treatment, you’ll quickly see how a laser solution delivers rapid ROI.

For a deeper dive into selecting and deploying the optimal laser cleaning system, we invite you to explore HBS Tech Co., Ltd. Their experienced engineers can guide you through:

Application Assessment: Detailed analysis of your cleaning volumes and material challenges.

Customized Solutions: Power classes, pulse modes, and automation platforms tailored to your needs.

Turnkey Support: Installation, training, and aftermarket service for uninterrupted operations.

Discover how HBS Tech’s laser cleaning machines can revolutionize your maintenance processes—boosting productivity, reducing environmental impact, and safeguarding equipment longevity. Visit www.hbs-lasers.com or email info@hbs-lasers.com today to request a consultation and personalized demonstration.