- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HBS-JZ115P

HBS

| Availability: | |

|---|---|

| Quantity: | |

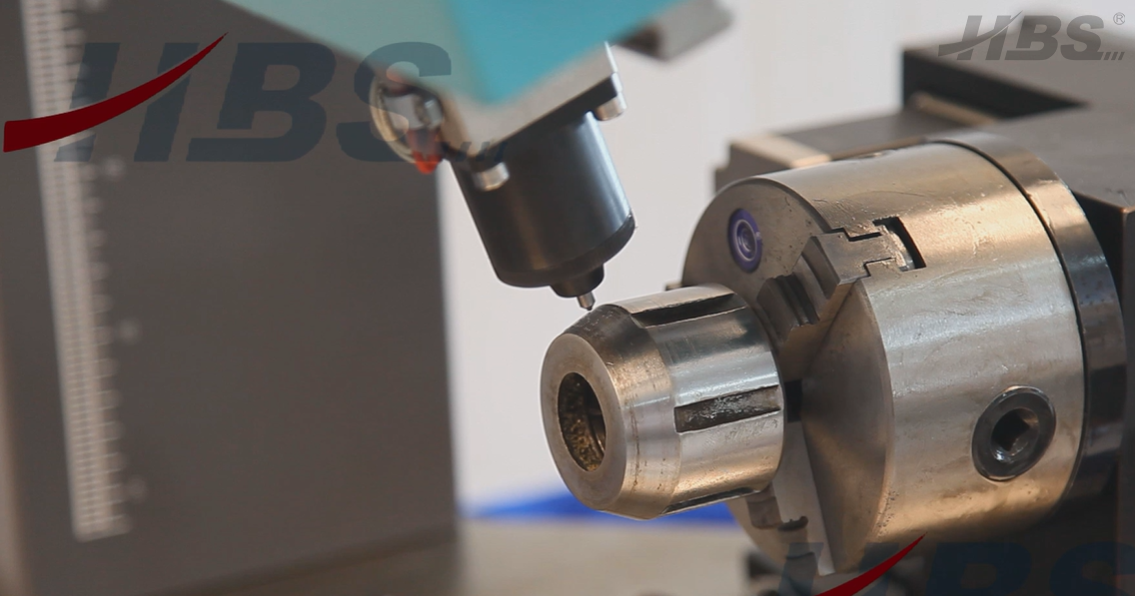

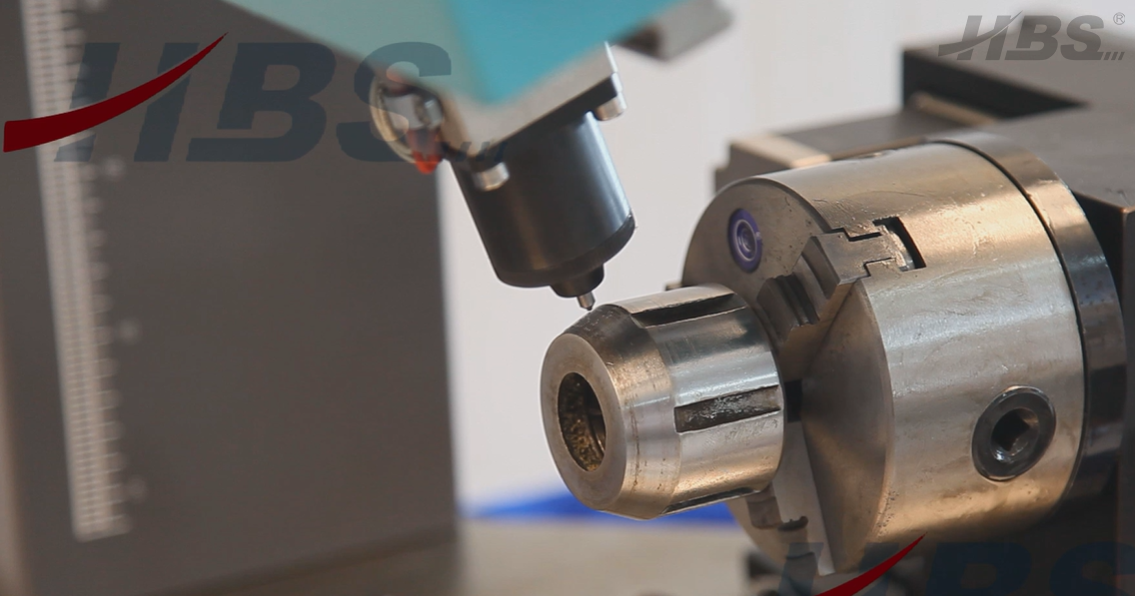

The Desktop Pneumatic Dot Peen Marking Machine JZ115P is a reliable, cost-effective solution designed for industrial labeling of metal and plastic components. Utilizing pneumatic drive technology, it creates permanent dot peen marks with consistent depth and clarity, making it ideal for medium-duty marking applications in workshops and production lines.

Pneumatic Drive System: High-frequency pneumatic actuator (300Hz max) generates dots with 0.1–1.2mm depth, ensuring durable marks on hard metals (up to 55 HRC) and engineering plastics.

Adjustable Marking Parameters: Digital control panel for easy adjustment of dot spacing (0.3–2mm), marking speed (50–200mm/s), and force (20–80N), adapting to different surface hardness and texture.

Compact Desktop Design: Space-efficient dimensions (350x280x220mm) with built-in air regulator, requiring only a 0.5–0.8MPa air supply for operation, suitable for limited workspaces.

Multi-Format Support: Marks text, numbers, logos, and 2D barcodes (Data Matrix, QR codes) via intuitive software, supporting CSV file imports for batch marking with serial number increment.

Reliable Performance: Industrial-grade aluminum alloy structure and dust-resistant design (IP54), ensuring 24/7 operation with minimal maintenance (annual lubrication of guide rails).

Perfect for medium-duty industrial labeling, the JZ115P excels in:

Metal Fabrication: Marking part numbers, batch codes, and inspection dates on steel plates, aluminum extrusions, and copper busbars for quality control.

Electronics Industry: Engraving serial numbers and certification marks on metal enclosures, connectors, and heat sinks in consumer electronics production.

Automotive Aftermarket: Labeling replacement parts (brackets, valves, filters) with traceable codes for warranty management and inventory control.

Plastic Manufacturing: Marking logos and product specifications on ABS plastic components, such as electrical switchgear and automotive interior parts.

Robust Pneumatic Technology: Delivers deeper, more consistent marks on hard materials compared to electric dot peen models, with a marking speed 20% faster than manual methods.

User-Friendly Operation: Plug-and-play setup with pre-calibrated parameters, reducing operator training time to 30 minutes for basic marking tasks.

Cost Efficiency: Low energy consumption (air-powered) and long-lasting components (marking needle lifespan: 500,000 dots), making it the most economical dot peen solution for medium-volume production.

Localized Support: Global network of service centers provides quick delivery of replacement parts (e.g., marking needles, air filters) and on-site maintenance for minimal downtime.

Model | HBS-JZ115P |

Marking content | Numbers, Chinese and English characters, graphics |

Engraving range | 150mmx100mm |

Repetitive accuracy | 0.05mm |

Marking Depth | 0.02-1mm(Depending on the material) |

Marking Speed | 1500-2000mm/Min |

Electricity demand | AC220V/±10%/50Hz |

Compressed air | 0.3-0.6Mpa |

Circumference | Φ5-100mm(Customized according to user needs) |

Power | <150W |

The Desktop Pneumatic Dot Peen Marking Machine JZ115P is a reliable, cost-effective solution designed for industrial labeling of metal and plastic components. Utilizing pneumatic drive technology, it creates permanent dot peen marks with consistent depth and clarity, making it ideal for medium-duty marking applications in workshops and production lines.

Pneumatic Drive System: High-frequency pneumatic actuator (300Hz max) generates dots with 0.1–1.2mm depth, ensuring durable marks on hard metals (up to 55 HRC) and engineering plastics.

Adjustable Marking Parameters: Digital control panel for easy adjustment of dot spacing (0.3–2mm), marking speed (50–200mm/s), and force (20–80N), adapting to different surface hardness and texture.

Compact Desktop Design: Space-efficient dimensions (350x280x220mm) with built-in air regulator, requiring only a 0.5–0.8MPa air supply for operation, suitable for limited workspaces.

Multi-Format Support: Marks text, numbers, logos, and 2D barcodes (Data Matrix, QR codes) via intuitive software, supporting CSV file imports for batch marking with serial number increment.

Reliable Performance: Industrial-grade aluminum alloy structure and dust-resistant design (IP54), ensuring 24/7 operation with minimal maintenance (annual lubrication of guide rails).

Perfect for medium-duty industrial labeling, the JZ115P excels in:

Metal Fabrication: Marking part numbers, batch codes, and inspection dates on steel plates, aluminum extrusions, and copper busbars for quality control.

Electronics Industry: Engraving serial numbers and certification marks on metal enclosures, connectors, and heat sinks in consumer electronics production.

Automotive Aftermarket: Labeling replacement parts (brackets, valves, filters) with traceable codes for warranty management and inventory control.

Plastic Manufacturing: Marking logos and product specifications on ABS plastic components, such as electrical switchgear and automotive interior parts.

Robust Pneumatic Technology: Delivers deeper, more consistent marks on hard materials compared to electric dot peen models, with a marking speed 20% faster than manual methods.

User-Friendly Operation: Plug-and-play setup with pre-calibrated parameters, reducing operator training time to 30 minutes for basic marking tasks.

Cost Efficiency: Low energy consumption (air-powered) and long-lasting components (marking needle lifespan: 500,000 dots), making it the most economical dot peen solution for medium-volume production.

Localized Support: Global network of service centers provides quick delivery of replacement parts (e.g., marking needles, air filters) and on-site maintenance for minimal downtime.

Model | HBS-JZ115P |

Marking content | Numbers, Chinese and English characters, graphics |

Engraving range | 150mmx100mm |

Repetitive accuracy | 0.05mm |

Marking Depth | 0.02-1mm(Depending on the material) |

Marking Speed | 1500-2000mm/Min |

Electricity demand | AC220V/±10%/50Hz |

Compressed air | 0.3-0.6Mpa |

Circumference | Φ5-100mm(Customized according to user needs) |

Power | <150W |