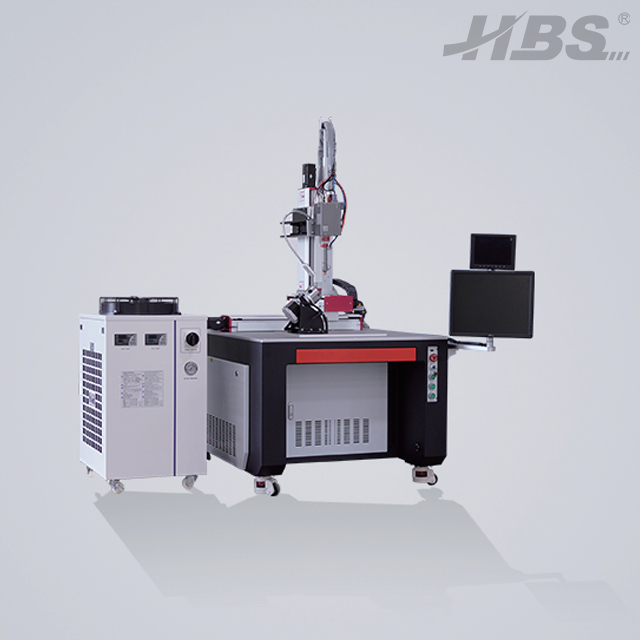

Electric Marking Machine

At HBS-Lasers, we recognize that precision isn't merely an added benefit; it's the core of what we do. Our Electric Marking Machines are more than just devices; they embody the precision and efficiency essential for your marking tasks. Experience the power of advanced marking technology as you browse our collection, seeing how ordinary marking needs transform into exceptional, high-precision results with our Electric Marking Machines. Your marking requirements, our expertise — together, we achieve marking excellence.

Features

High Precision

Electric Marking Machines are revolutionizing marking accuracy across industries. They enable precise marking in applications like part identification, serial number engraving, and logo printing on metals, plastics, and more.

Versatile

Electric Marking Machines are transforming marking flexibility in various fields. They support diverse marking tasks, from batch marking on production lines to customized marking for unique workpieces, suitable for metal, non-metal, and composite materials.

Efficient

Electric Marking Machines are boosting marking efficiency in multiple sectors. With fast marking speeds and automated operation capabilities, they enhance productivity in areas such as industrial manufacturing, aerospace, and electronics production.

Durable

Electric Marking Machines are ensuring long-lasting marking performance in different industries. Featuring robust components and stable laser or dot-peen systems, they maintain reliable operation for prolonged periods in harsh industrial environments.

Application

Capably marking a vast range of workpieces from small to large, Electric Marking Machines, with their extensive product lineup, facilitate the automation of the marking process across diverse industries.

Enable Diverse Material Marking

Electric Marking Machines can accurately mark on metals, plastics, wood, and other materials. Whether it's permanent part number marking on metal components or logo printing on plastic products, they ensure clear, durable, and high-quality marks, meeting the diverse marking needs of different industries.

Enhance Product Traceability

By marking serial numbers, batch codes, and other identifiers on products, Electric Marking Machines make it easy to track products throughout their lifecycle. This is invaluable for quality control, warranty services, and anti-counterfeiting efforts, helping businesses manage their products more efficiently.

Support Flexible Customized Marking

Electric Marking Machines allow for easy customization of marks, such as personalized logos, special symbols, or variable data. This flexibility enables businesses to meet the unique marking needs of custom orders and small production runs, enhancing their ability to cater to niche markets.

Company Advantage(Why choose us)

No expertise needed. We'll support you throughout the entire process.

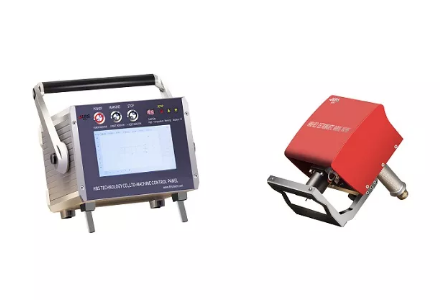

Advanced Technology

Our Electric Marking Machines adopt cutting-edge laser and dot-peen technologies, ensuring high-precision, clear, and durable markings on various materials.

Customization Capability

We offer tailored solutions to meet your unique marking requirements, from custom marking patterns to specialized machine configurations.

Comprehensive After-sales Service

FAQs

Contact Us

Our company is a leading enterprise in the marking equipment industry, specializing in the research, production and sales of Electric Marking Machines.

Related Blogs

Keep in Touch With Us

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

Mob:+86-10-88585032 +86-13811024670

sales03@hbslaser.com