Product Description

The HBS Laser Marking Machine is an advanced marking solution that delivers superior quality and performance. With various types available, including Fiber, MOPA, CO2, and UV lasers, our machines are engineered to provide fast and accurate marking on metals, plastics, wood, glass, and more. They produce permanent, high-resolution marks that are resistant to abrasion, solvents, and heat, ensuring robust traceability and identification. Our systems are highly energy-efficient and environmentally friendly, representing a smart investment for any manufacturing operation.

Why Our Laser Marking Machines Stand Out

High-Precision Marking

Achieve ultra-fine and clear marks with sharp edges.

Permanent Results

Markings are wear-resistant and durable, ensuring long-term traceability.

Low Maintenance

Solid-state design guarantees a long lifespan with minimal upkeep.

Energy Efficient

Our machines consume less power compared to traditional marking methods.

Where Precision Meets Industry: Our Laser Marking Solutions

Here’s how our laser marking machines are transforming key industries by providing precise, permanent, and efficient marking solutions.

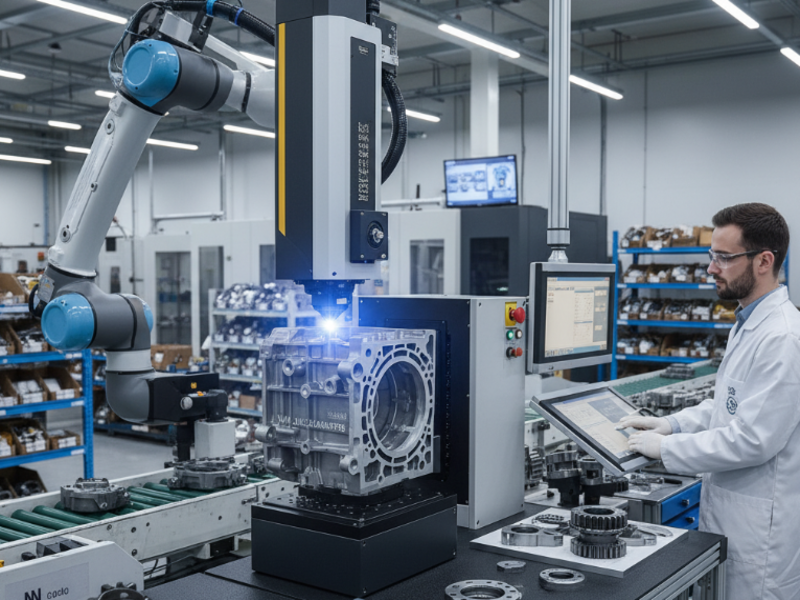

Automotive Industry

Our laser marking systems are indispensable for automotive parts and components. They are used for marking unique identifiers like VIN numbers, batch codes, and serial numbers on metal parts, ensuring full traceability throughout the supply chain. The permanent marks withstand extreme conditions, including high temperatures and exposure to chemicals, which is critical for long-term safety and quality control.

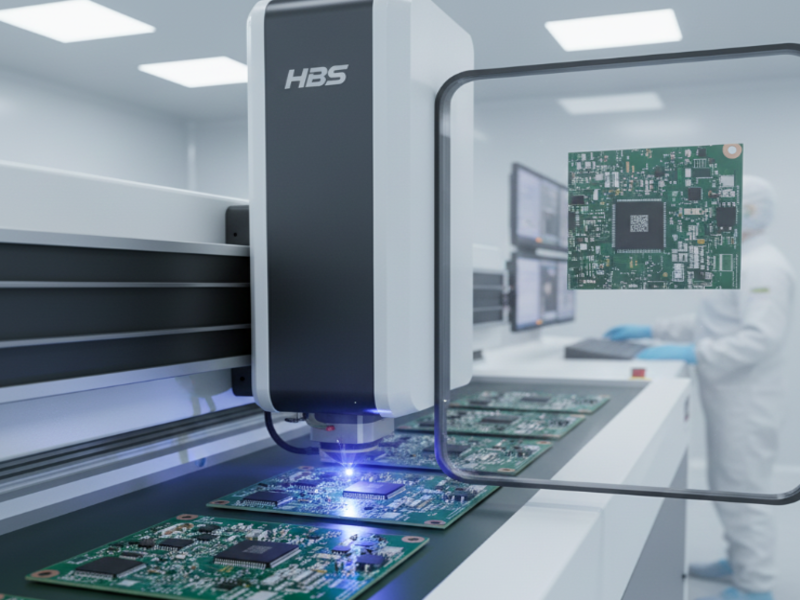

Electronics Manufacturing

In the fast-paced electronics sector, precision is everything. HBS laser markers are perfect for non-contact, high-speed marking on sensitive components like PCBs, semiconductors, and integrated circuits. The fine laser beam ensures that even the smallest marks, like QR codes or data matrices, are perfectly legible without causing any thermal damage to the delicate parts.

Aerospace Industry

In aerospace, where component integrity is non-negotiable, our systems provide the permanent identification required for high-stress parts. Laser marking is used for part identification and traceability on engine components, turbine blades, and structural parts. The marks are durable, lightweight, and comply with strict industry standards, making them a reliable solution for critical applications.

Product Advantages

Innovative R&D Capabilities

HBS continuously invests in R&D to innovate and upgrade our products, ensuring we provide cutting-edge laser solutions that meet evolving customer needs.

Comprehensive Product Range

We offer a variety of laser technologies (Fiber, CO2, UV, MOPA) to cater to diverse materials and application requirements.

Strict Quality Control

All our systems are manufactured under the ISO9001 quality control system, with strict supervision from design to delivery, guaranteeing excellent performance and reliability.

Global Presence & Support

Our laser systems are used worldwide, and we provide reliable solutions and technical support to numerous well-known companies globally.

Why choose HBS

Since 2001, HBS has been a leading laser equipment supplier in China, providing reliable and sustainable solutions to countless businesses.

20+ Years of Industry Leadership

Our vision is to ensure customer satisfaction by providing reliable, high-quality, and innovative solutions tailored to your specific needs.

Customer-Centric Approach

We offer professional ODM services, including custom software and hardware development, to meet your unique project requirements.

ODM Service

FAQs

Contact Us

Laser Cutting/Marking/Welding/Cleaning Machine Manufacturer

Related Blogs

Keep in Touch With Us

Get in touch with our team of laser experts today and discover how our solutions can revolutionize your marking process. Whether you're looking to improve efficiency, ensure traceability, or simply learn more about our technology, we're here to help. Contact us now for a free consultation or a product demo.

Mob:+86-10-88585032 +86-13811024670

E-mail:sales03@hbslaser.com