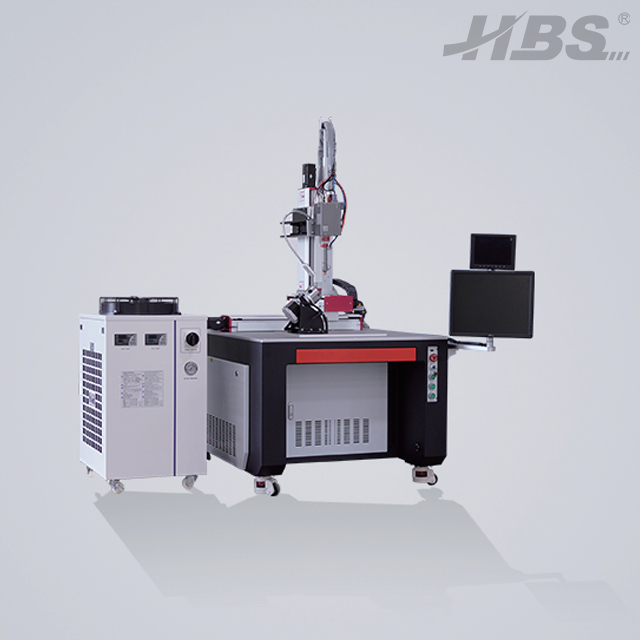

Pneumatic Marking Machine Series

HBS Lasers offers a diverse range of pneumatic marking machines designed to meet various industrial marking needs. Our pneumatic systems utilize compressed air to drive the marking process, providing robust and consistent performance for permanent marking applications.

1. Handheld Pneumatic Dot Peen Engraving Machine HBS-380P This portable and lightweight marking tool is ideal for on-site marking of metal components. It offers a marking area of 30×80 mm, with options for larger areas like 30×130 mm, making it versatile for different workpiece sizes. The HBS-380P is designed for ease of use, ensuring clear and precise markings on various metal surfaces.

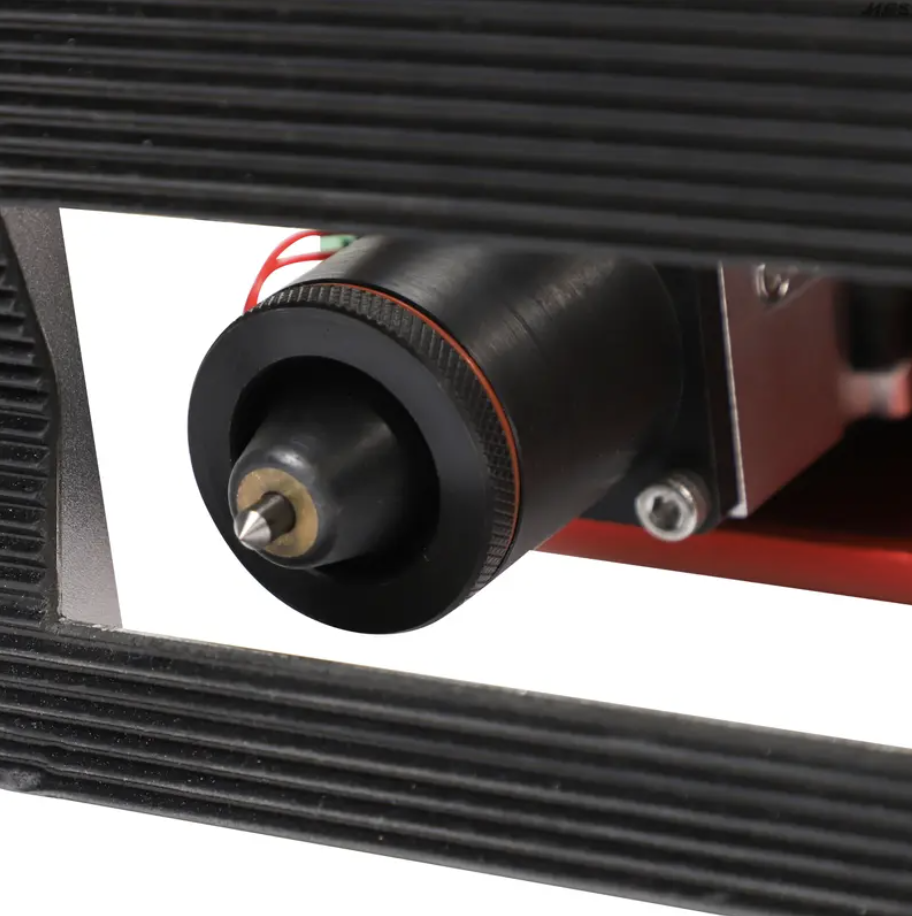

2. Desktop Pneumatic Dot Peen Marking Machine JZ115P The JZ115P is a compact desktop solution suitable for industrial labeling of metal and plastic components. Utilizing pneumatic drive technology, it creates permanent dot peen marks with consistent depth and clarity, making it ideal for medium-duty marking applications in workshops and production lines.

3. Industrial Pneumatic Nameplate Marker Designed for permanent marking on metal nameplates, tags, and badges, this robust solution is ideal for equipment identification, safety signage, and compliance labeling in industrial environments. Its heavy-duty pneumatic drive system ensures deep, legible marks on various metal substrates.

4. Portable Pneumatic Dot Peen Marking Machine HBS-380P Similar to the handheld model, this portable marking machine offers flexibility for marking large or heavy workpieces. Its compact design and pneumatic operation make it suitable for diverse marking tasks across various industries.

Features

High Durability and Industrial-Grade Build

Our pneumatic marking machines are engineered for long-lasting performance in demanding industrial environments, ensuring consistent and reliable operation over time.

Precision and Consistency

Advanced dot peen technology guarantees clear, uniform, and permanent markings, making them ideal for serial numbers, logos, barcodes, and traceability marks.

Portable and Flexible Operation

Compact handheld and portable designs allow for easy transportation and use on-site or in workshops, providing maximum flexibility for various marking tasks.

User-Friendly Controls

Intuitive control panels and simple setup procedures ensure fast integration into production lines, reducing operator training time and increasing efficiency.

Application

HBS Pneumatic Marking Machines are widely used across multiple industries to provide durable, precise, and efficient identification solutions. In the automotive industry, they are used for marking serial numbers, chassis numbers, and metal components for traceability and quality control. In aerospace and electronics, these machines ensure permanent markings on critical parts, components, and metal plates, maintaining compliance with industry standards. The manufacturing and machinery sectors rely on pneumatic marking for nameplates, safety signs, and production batch labeling. Additionally, handheld and portable models are ideal for on-site marking of large, irregular, or heavy workpieces, providing flexibility for workshops, assembly lines, and maintenance operations.

Quality Assurance & Compliance

At HBS Lasers, quality and compliance are our top priorities. Every pneumatic marking machine undergoes rigorous testing and inspection to ensure consistent performance, precision, and durability. Our production process adheres to strict international standards, including ISO and CE certifications, guaranteeing that each machine meets the highest quality requirements. From component fabrication to final assembly, every stage is carefully monitored by our skilled engineers. This commitment to quality ensures that our machines deliver permanent, accurate, and reliable markings, even in demanding industrial environments.

Technical Support & Service

HBS Lasers provides comprehensive technical support and professional service to ensure our pneumatic marking machines operate at peak performance. Our experienced engineering team offers full guidance on installation, operation, and process optimization, helping clients integrate machines seamlessly into their production lines. We also provide remote troubleshooting and on-site support to quickly resolve any issues, minimizing downtime and maintaining efficiency. Additionally, regular maintenance programs, spare parts supply, and operator training are available to ensure long-term reliability. With a strong global service network, HBS is committed to delivering prompt, efficient, and professional support to every customer, wherever they operate.

Customer Success & Global Presence

Trusted by Global Partners

HBS Pneumatic Marking Machines are trusted by customers across the automotive, aerospace, electronics, and manufacturing industries worldwide. With years of experience and consistent product quality, we have established long-term partnerships with clients in over 50 countries.

Proven Results Across Industries

From Asia and Europe to North and South America, our marking machines operate in diverse industrial environments, delivering precise, durable, and reliable results while complying with international standards.

Strong Global Distribution Network

We take pride in supporting our partners’ success through innovative solutions and dedicated after-sales service. Our global technical team provides prompt assistance to ensure uninterrupted production and optimal machine performance.

Commitment to Long-Term Partnerships

By combining advanced manufacturing capabilities with worldwide service coverage, HBS aims to create sustainable, long-term partnerships that drive efficiency, traceability, and growth for our customers across the globe.

Company Advantage(Why choose us)

With years of expertise in pneumatic marking and industrial engraving, HBS has developed deep knowledge of customer needs and industry standards, ensuring reliable and efficient marking solutions.

Decades of Industry Experience

Our production facilities are equipped with precision CNC machines, automated assembly lines, and strict quality control systems, guaranteeing durable, high-performance marking machines.

Advanced Manufacturing Capabilities

A dedicated engineering and R&D team continuously improves machine design, enhances automation, and develops new technologies to meet evolving industrial marking requirements.

Strong R&D and Innovation

FAQs

Contact Us

Looking for the perfect Pneumatic Marking Machine solution for your production needs? HBS Lasers is ready to help you select the right model and provide personalized technical guidance. Whether you are setting up a new production line or optimizing an existing one, we offer tailored solutions to ensure precision, reliability, and efficiency.

Related Blogs

Keep in Touch With Us

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.Our professional team will provide you with detailed product information, answer your questions, and tailor the best solution to meet your needs.

mob:+86-10-88585032 +86-13811024670

sales03@hbslaser.com