- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HBS-GQ-20J

| Availability: | |

|---|---|

| Quantity: | |

Machine Model | HBS-GQ-20J |

Laser Source | Raycus Advanced+ |

Average power | 20 watts |

Laser Power Lifetime | 100,000 hours (Theoretical data) |

Fiber cable length | 2.5m |

Cooling | Air cooling |

Marking Wavelength | 1064nm |

Beam Quality | 1.5 |

Laser Repetition Frequency | 100kHz |

Marking Depth | 0-1.5mm (adjustable with power setting, speed, materials) |

Marking Speed | 12000mm/s |

Minimum Line Width | 0.01mm |

Minimum Character Size | 0.05mm |

Repetition Precision | ±0.001mm |

Standard Marking Area(mm) | 110*110 |

Optional Marking Area(mm) | 75*75, 150*150, 160*160, 175*175, 200*200, 300*300 |

Focal Length | Depends on marking area requirements |

Power Consumption | ≤500W |

Machine Requirements | AC220V(±10%), 50Hz(±10%), 10A |

Operation Temperature | -10℃-60℃ |

Humidity | 5-95% |

Control System | Win7, Win8, Win10, Win XP, |

RAM | 2GB-16GB |

HDD | 500G |

Marking Formats | AI., PLT., DXF., TIFF., PNG., BMP., JPG. etc. |

Computer Connection | 2.0USB |

Software | Ezcad 2.9.0 |

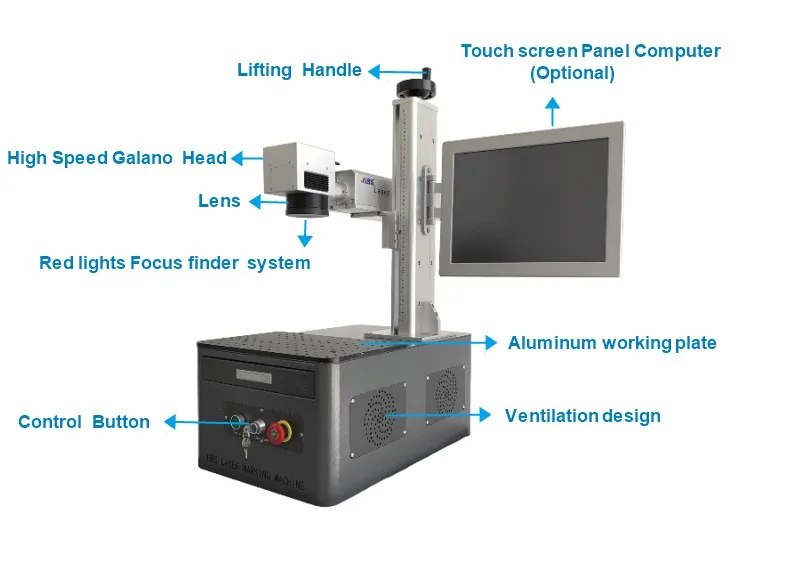

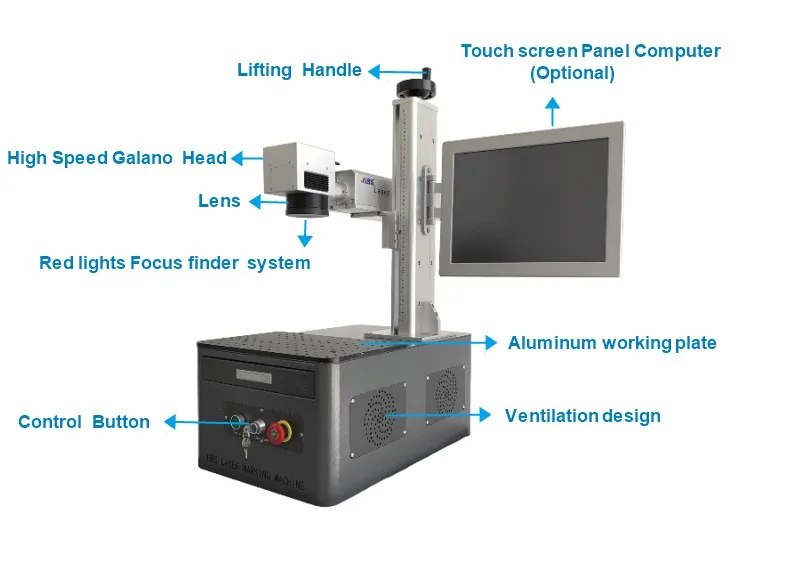

The Desktop Metal Marking Fiber Laser Marking Machine is a compact, high-performance solution designed for precision marking on metal workpieces in benchtop environments. Engineered for small-to-medium batch production, it combines the versatility of fiber laser technology with user-friendly operation, making it ideal for workshops, research labs, and small-scale manufacturing.

High-Precision Marking: 20W fiber laser source achieves 500dpi resolution with a 100x100mm marking area, enabling clear text (0.5mm height), logos, and 2D barcodes on metal surfaces (stainless steel, aluminum, copper).

Compact Design: Space-saving footprint (400x300x200mm) fits seamlessly on benchtops or mobile workstations, with a lightweight design (15kg) for easy relocation between work areas.

User-Friendly Interface: Touchscreen control panel with pre-installed templates for quick design setup, supporting text, serial numbers, and logo imports from USB drives or PCs.

Material Adaptability: Adjustable power (10–100W) and speed (100–8000mm/s) for optimal marks on different metal finishes: matte aluminum, polished stainless steel, and coated copper with consistent contrast.

Safety Features: Protective interlock switch and UV-shielding cover, compliant with Class 1M laser safety standards (IEC 60825-1), ensuring operator safety during continuous use.

Suited for diverse metal marking needs, this machine is used in:

Jewelry Manufacturing: Engraving hallmarks, serial numbers, and custom designs on gold, silver, and platinum jewelry with micron-level precision.

Electronics Production: Marking serial numbers and component IDs on metal enclosures, heat sinks, and connectors for traceability in electronic device assembly.

Tool & Die Making: Engraving manufacturer logos and part numbers on carbide tools, punches, and dies for asset management and anti-counterfeiting.

Educational & Research Labs: Marking test samples and prototypes with unique identifiers for material science experiments and mechanical testing.

Balanced Performance: Combines professional-grade marking quality with a compact form factor, ideal for businesses seeking efficiency without compromising on precision.

Cost-Effective Solution: Affordable price point with low maintenance (annual lens cleaning) and long laser diode lifespan (100,000 hours), providing a rapid return on investment for SMEs.

Flexible Connectivity: Supports USB, Ethernet, and Wi-Fi for design transfer and software updates, with compatibility for popular design tools like CorelDRAW and AutoCAD.

Dedicated Support: Includes a comprehensive starter kit, online video tutorials, and a 24/7 customer hotline to assist with any operational questions or technical issues.

Machine Model | HBS-GQ-20J |

Laser Source | Raycus Advanced+ |

Average power | 20 watts |

Laser Power Lifetime | 100,000 hours (Theoretical data) |

Fiber cable length | 2.5m |

Cooling | Air cooling |

Marking Wavelength | 1064nm |

Beam Quality | 1.5 |

Laser Repetition Frequency | 100kHz |

Marking Depth | 0-1.5mm (adjustable with power setting, speed, materials) |

Marking Speed | 12000mm/s |

Minimum Line Width | 0.01mm |

Minimum Character Size | 0.05mm |

Repetition Precision | ±0.001mm |

Standard Marking Area(mm) | 110*110 |

Optional Marking Area(mm) | 75*75, 150*150, 160*160, 175*175, 200*200, 300*300 |

Focal Length | Depends on marking area requirements |

Power Consumption | ≤500W |

Machine Requirements | AC220V(±10%), 50Hz(±10%), 10A |

Operation Temperature | -10℃-60℃ |

Humidity | 5-95% |

Control System | Win7, Win8, Win10, Win XP, |

RAM | 2GB-16GB |

HDD | 500G |

Marking Formats | AI., PLT., DXF., TIFF., PNG., BMP., JPG. etc. |

Computer Connection | 2.0USB |

Software | Ezcad 2.9.0 |

The Desktop Metal Marking Fiber Laser Marking Machine is a compact, high-performance solution designed for precision marking on metal workpieces in benchtop environments. Engineered for small-to-medium batch production, it combines the versatility of fiber laser technology with user-friendly operation, making it ideal for workshops, research labs, and small-scale manufacturing.

High-Precision Marking: 20W fiber laser source achieves 500dpi resolution with a 100x100mm marking area, enabling clear text (0.5mm height), logos, and 2D barcodes on metal surfaces (stainless steel, aluminum, copper).

Compact Design: Space-saving footprint (400x300x200mm) fits seamlessly on benchtops or mobile workstations, with a lightweight design (15kg) for easy relocation between work areas.

User-Friendly Interface: Touchscreen control panel with pre-installed templates for quick design setup, supporting text, serial numbers, and logo imports from USB drives or PCs.

Material Adaptability: Adjustable power (10–100W) and speed (100–8000mm/s) for optimal marks on different metal finishes: matte aluminum, polished stainless steel, and coated copper with consistent contrast.

Safety Features: Protective interlock switch and UV-shielding cover, compliant with Class 1M laser safety standards (IEC 60825-1), ensuring operator safety during continuous use.

Suited for diverse metal marking needs, this machine is used in:

Jewelry Manufacturing: Engraving hallmarks, serial numbers, and custom designs on gold, silver, and platinum jewelry with micron-level precision.

Electronics Production: Marking serial numbers and component IDs on metal enclosures, heat sinks, and connectors for traceability in electronic device assembly.

Tool & Die Making: Engraving manufacturer logos and part numbers on carbide tools, punches, and dies for asset management and anti-counterfeiting.

Educational & Research Labs: Marking test samples and prototypes with unique identifiers for material science experiments and mechanical testing.

Balanced Performance: Combines professional-grade marking quality with a compact form factor, ideal for businesses seeking efficiency without compromising on precision.

Cost-Effective Solution: Affordable price point with low maintenance (annual lens cleaning) and long laser diode lifespan (100,000 hours), providing a rapid return on investment for SMEs.

Flexible Connectivity: Supports USB, Ethernet, and Wi-Fi for design transfer and software updates, with compatibility for popular design tools like CorelDRAW and AutoCAD.

Dedicated Support: Includes a comprehensive starter kit, online video tutorials, and a 24/7 customer hotline to assist with any operational questions or technical issues.