- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-31 Origin: Site

Laser marking machines have become an essential tool in modern manufacturing. They allow businesses to mark materials with permanent, precise, and legible marks, which is crucial in industries that require traceability and product identification. Whether for serial numbers, barcodes, logos, or QR codes, the laser marking machine has revolutionized marking processes, offering advantages over traditional methods like engraving and screen printing. In this article, we will dive into the details of what a laser marking machine is, how it works, and why it's increasingly used in various industries.

A laser marking machine uses a focused beam of light to create permanent markings on the surface of materials. These marks can be in the form of text, graphics, serial numbers, or barcodes. Unlike traditional methods, such as engraving or inkjet printing, laser marking is a non-contact process, which means there‘s no physical wear on the material surface. It works by focusing high-energy laser beams onto the material's surface, causing a reaction that results in visible and permanent marks.

Laser marking machines operate through a precise and controlled process. At the core, these machines use an oscillator to generate a laser beam, which is then focused on the target material using a scanning mirror and focusing lens. As the beam hits the surface, it alters the material's properties, creating a permanent mark. The marking process varies depending on the material being marked and the energy used in the laser beam.

The heat from the laser beam can cause various reactions, such as engraving, etching, or discoloration of the material. The result is a high-contrast, durable mark that doesn't wear or fade over time, even under harsh conditions.

Laser marking machines are widely preferred over traditional methods due to several advantages that increase efficiency, reduce costs, and ensure high-quality output.

Laser marks are highly precise and permanent. Unlike ink-based methods that can fade or wear off, laser marking creates indelible marks that are easy to read even after long periods. The high precision of the machine ensures that each mark is accurate, which is particularly important in industries where tracking and identification are critical.

Unlike traditional engraving or printing, which may require consumables like ink or chemicals, laser marking is a more environmentally friendly process. Since no consumables are used, it reduces waste and lowers operating costs. Additionally, laser marking machines are more energy-efficient, making them cost-effective over time.

Laser marking machines are fast, which significantly boosts production speed. They can mark thousands of parts per hour, ensuring that manufacturers can meet high-volume demands. The automation of the marking process reduces human errors and speeds up turnaround times.

Laser marking machines are incredibly versatile. They can be used on a wide range of materials, including metals, plastics, ceramics, glass, and even organic materials. Depending on the type of laser used, the machine can engrave, etch, or discolor materials to create the desired effect.

For industries dealing with high-volume parts, investing in a laser marking machine can drastically reduce production time and improve operational efficiency.

Laser marking machines come in various types, each suited for different materials and applications. Here, we will explore some of the most common types used in the industry.

CO2 lasers are widely used for marking non-metallic materials like wood, plastic, and glass. They produce a long-wavelength light (10600 nm), which is ideal for organic materials. CO2 laser marking machines are often used in the food packaging and textile industries for product labeling.

Pros:

Best for non-metal materials

High-speed marking for thicker materials

Cons:

Not ideal for metals unless pre-treated

Higher operational costs due to energy consumption

Fiber lasers are the go-to choice for metal marking. These machines use a solid-state laser with a wavelength of around 1064 nm, which is highly effective for marking metals like stainless steel, aluminum, and titanium. Fiber lasers are efficient and ideal for fine detailing, which makes them suitable for applications in the electronics and aerospace industries.

Pros:

Suitable for metals and hard materials

Minimal maintenance and low operational costs

High marking precision

Cons:

May not work as efficiently on certain plastics

Higher upfront cost

Green lasers operate at a wavelength of 532 nm, making them suitable for highly reflective materials. These lasers are often used in marking delicate or high-precision materials such as silicon wafers, solar cells, and other semiconductor devices.

Pros:

Ideal for highly reflective materials

High precision and excellent marking contrast

Cons:

Lower power, limiting speed

Best suited for small-scale marking applications

UV lasers are capable of creating marks without generating heat, making them perfect for cold marking applications. These machines are typically used for marking plastics, glass, and medical devices where minimal thermal impact is crucial.

Pros:

Non-thermal process, preserving material integrity

Excellent for marking sensitive materials like medical devices and electronics

Cons:

High cost

Slower marking speed compared to other lasers

Tip:

When choosing a laser marking machine, consider the material you will be working with, as well as the marking speed and required precision. This will help you select the right technology for your needs.

Laser marking machines are used across various industries for a wide range of applications. The ability to create permanent, legible marks on different materials makes them indispensable in many sectors.

Laser marking plays a key role in product traceability. In industries such as automotive and aerospace, parts need to be permanently marked with serial numbers, barcodes, and QR codes to track their production history. Laser marking ensures that these marks are legible and resistant to wear.

In the electronics industry, laser marking machines are used to mark small components, including PCBs (Printed Circuit Boards). The precision of the laser allows for fine markings on tiny electronic parts without damaging the components.

Medical devices must meet strict regulatory standards, including permanent marking for identification. Laser marking is ideal for this application as it ensures high-contrast, readable marks that remain intact even after sterilization processes.

Laser marking is used extensively in the packaging industry to mark expiry dates, batch numbers, and barcodes on packaging materials. This provides a durable, eco-friendly alternative to ink-based printing methods.

For companies in regulated industries, like medical devices or aerospace, using laser marking machines ensures compliance with traceability standards and avoids potential issues during audits or inspections.

In summary, laser marking machines offer precision, speed, and permanence, making them superior to traditional methods. These versatile machines cater to industries such as automotive, electronics, medical, and packaging. With growing demands for durable product identification, investing in a laser marking machine can enhance your manufacturing efficiency.

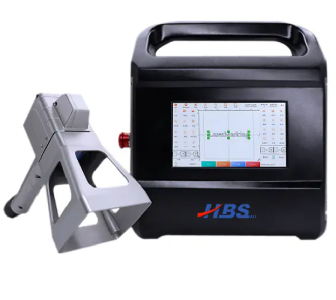

By selecting the right machine for your materials, you can improve the quality of your marking process. HBS offers innovative laser marking solutions that help streamline production and meet diverse marking needs.

A: A laser marking machine uses a focused laser beam to create permanent marks on materials like metals, plastics, and ceramics. It is widely used for text, graphics, serial numbers, and QR codes.

A: The machine focuses a laser beam onto the material's surface, causing changes in the material's properties. This creates precise, permanent marks without damaging the material.

A: Laser marking machines provide high precision, durability, and speed, making them ideal for mass production and ensuring permanent, legible marks on various materials.